Comprehending Tight Connections: A Thorough Examination

In advanced technology, guaranteeing trustworthiness and safeguarding in electrical connections is more crucial than ever. Here is where hermetically encased connectors come into play, offering a unique solution for environments that demand robustness and protection to external elements. These connectors are designed to create an airtight seal, preventing the ingress of moisture, dust, and additional contaminants that could jeopardize electronic systems.

Comprehending how hermetic sealed connectors work requires delving into their design and performance. Such connectors utilize different materials and design methods to offer a secure connection while maintaining the purity of the sealed environment. By exploring the intricacies behind these components, we can value their vital role in industries ranging from aerospace to medical, where dependability is non-negotiable.

Key Features of Sealed Hermetic Connectors

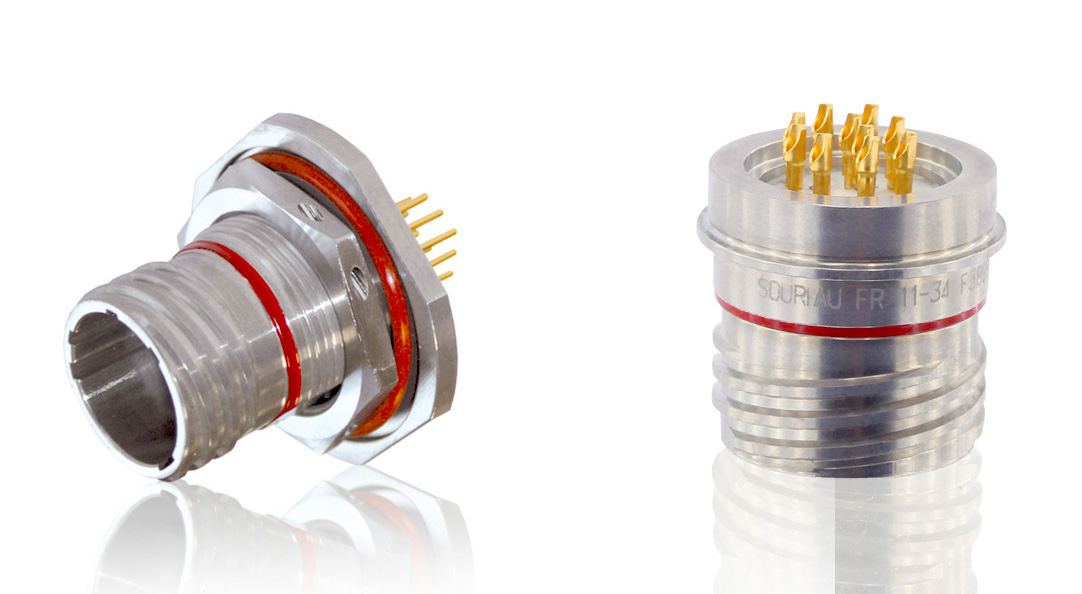

Hermetic sealed connectors are designed to provide a reliable connection in demanding environments where moisture, dust, and other contaminants pose significant risks. The key feature of these connectors is their ability to form an hermetic seal, preventing the penetration of gases and liquids. This sealing is typically achieved through the use of metal-to-glass seals or elastomeric materials that ensure a durable barrier against environmental elements. This feature is particularly crucial in sectors such as aerospace, military, and healthcare, where breakdown due to environmental factors can result in severe consequences.

Additionally, another significant trait of hermetic sealed connectors is their ability to maintain electrical performance while being exposed to extreme conditions. These connectors are engineered to endure a wide range of heat levels, pressures, and vibrations, ensuring that they function effectively even in the harshest conditions. The materials used in the construction of hermetic connectors are carefully selected to resist rust and deterioration, providing durability and reliable operation over time. This resilience makes them a favored choice for applications that require consistent and reliable performance.

Moreover, hermetic sealed connectors often come with specialized designs tailored to specific uses. This includes options for different connector layouts, dimensions, and mounting styles, allowing for versatility in different contexts. Tailoring further enhances their utility, enabling designers to integrate these connectors seamlessly into advanced setups. This flexibility, combined with their safeguarding features, makes hermetic sealed connectors an critical component in applications where trustworthiness and durability are of utmost importance.

Applications of Sealed Connectors

Sealed connectors are crucial in sectors requiring strong environmental protection. One of the main uses is in aerospace and defense sectors, where these connectors ensure that sensitive electronic equipment remains operational under extreme conditions. The connectors’ ability to prevent moisture, dirt, and contaminants from entering electrical systems is essential for maintaining performance during missions that may involve high altitudes or rugged terrains.

A significant use is in the medical field. In this field, hermetic connectors are used in devices that must remain clean and operational, such as surgical instruments and diagnostic devices. The sealing allow for the combination of electrical links and medical components without threatening pollution, ensuring safety and dependability in healthcare. This feature is especially critical in devices that are used in surgical procedures where any breach in the sealing could lead to significant medical issues.

Sealed connectors are also increasingly found in the automotive industry, especially in electric-powered and hybrid-powered vehicles. These devices play a crucial role in battery management systems and other electronic components that require protection from environmental factors. By preventing moisture and contaminants out, sealed connectors enhance product longevity and dependability, contributing to the overall efficiency and security of contemporary automobiles.

Benefits of Using Hermetic Sealed Connectors

One of the primary benefits of hermetic sealed connectors is its outstanding protection against environmental factors. These connectors are designed to be sealed tight, preventing humidity, dust, and various impurities from infiltrating. This feature is vital in harsh environments, such as aerospace, military, and outdoor applications, where environmental exposure can result in equipment failure. By ensuring a secure seal, hermetic connectors enhance the durability and dependability of the electronic components they connect.

Another notable benefit is its ability to preserve signal integrity. Hermetic sealed connectors are engineered to minimize the risk of interference, guaranteeing that signals remain distinct and stable. This quality is particularly important in high-frequency applications, where any deterioration in signal fidelity can cause performance problems. By utilizing hermetic sealed connectors, designers can enhance the overall performance and precision of their systems.

In addition, the durability of hermetic sealed connectors adds to their long-term value. These connectors are made from robust materials that can withstand extreme temperatures and mechanical stresses. Their strength not only reduces the likelihood of maintenance and replacement but also enhances the safety of the systems they serve. As a result, investing in hermetic sealed connectors can result in significant cost savings over time, as well as greater operational efficiency.